The HAAKE RotoVisco® 1 is a classical rotational rheometer.The use of a true CR motor in combination with a frictionless torque measurement system makes the instrument precise and reliable. It can be equipped with all the HAAKE Series 1 temperature control systems and the whole range of measurement geometries, making this rheometer a truly versatile instrument. Featuring an automatic lift system with auto-zero and thermo-gap functions, the HAAKE RotoVisco 1 is unique in its class.

Typical test methods:

Flow curves, time and temperature dependent properties, yield point determination, creep/recovery, multiwave acquisition, etc.

Automatic Lift

The correct geometry of the sample to be characterized is essential for performing a reliable rheological measurement. For this reason, the HAAKE RotoVisco® 1 is equipped with an automatic lift which guarantees a reproducible and highly accurate positioning of the measuring geometries.

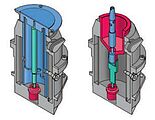

Motor technology

The different motor technologies used for the HAAKE RotoVisco® 1 device are specially adapted to the specific application fields of each instrument. The HAAKE RotoVisco® 1 motor is based on an extremely precise rate controlled actuation with a choice of 100 tabulated pre-defined shear-rates.

Temperature control

The HAAKE RotoVisco® 1 is factory modular regarding the temperature control systems. Each instrument is available with a large variety of devices, ranging from liquid temperature controlled cylinder systems to Peltier temperature controlled parallel or cone and plate systems.

Design and materials

The HAAKE RotoVisco® 1 is a combination of an outstanding design and modern industrial manufacturing. The frame of the HAAKE Series 1 is made from polymer concrete, a compound which guarantees high mechanical stiffness, high vibration damping, fast temperature equilibration and good resistance against solvents. This material allowed the renowned design studio ID-design to create original and functional volumes.

Temperature control units

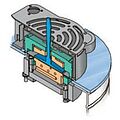

TCL/Z

Liquid temperature controlled receptacle for cylinder measuring systems or plate insert MP61, with direct contact of the thermal fluid from -20 °C up to +200 °C. A sample cover with integrated solvent trap guarantees very exact measurings. An external circulator is required.

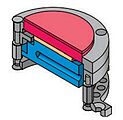

TCP/P

Peltier temperature controlled measuring plate for parallel plate or cone & plate sensors in the range from -40 °C up to +180 °C. An external heat exchanger or cooling unit is required.

TCE/PC

Electrically temperature controlled measuring plate with active cone heater for parallel plate or cone & plate sensors in the range from +30 °C up to +350 °C. The use of sensors with ceramic shanks minimizes heat loss. With a cooling circulator the range can be extended down to -20 °C.

Display and Control Unit

The display and control unit of the HAAKE RotoVisco® 1 is used for manual operation of the lift and the gap setting. It also allows to set pre-selected shear rates and to intervene in PC-controlled measurements. The color display monitors freely selectable rheological and instrument-specific data on-line. Data can be displayed numerically as well as graphically. Complex measuring sequences are carried out at the touch of a button, without using a PC.

Typical measuring geometries

The HAAKE RotoVisco® 1 instrument is compatible with a whole range of sensor systems made from titanium for the rotating part and stainless steel for the stationary part. Aluminum is used for the disposable systems. For high temperature applications the geometries are equipped with a ceramic shaft to prevent excessive heat loss.

| Model | HAAKE RotoVisco® 1 | |||

| Typical Sensor System | Shear rate (1/s) | Viscosity (mPas) | ||

| Double gap cylinder system DG4 | 0.5 - 3,300 | 1 - 3.8*105 | ||

| Cylinder Ø 34 mm ISO 3219 Z34 DIN | 0.2 - 1,300 | 1 - 2.4*106 | ||

| Cylinder Ø 20 mm ISO 3219 Z20 DIN | 0.2 - 1,300 | 3.7 - 1.2*107 | ||

| Cylinder Ø 10 mm ISO 3219 Z10 DIN | 0.2 - 1,300 | 30 - 1.0*108 | ||

| Cylinder Ø 41 mm DIN 53018 Z41 | 0.3 - 2,300 | 1 - 9.6*105 | ||

| Cylinder Ø 38 mm DIN 53018 Z38 | 0.15 - 900 | 1 - 3.0*106 | ||

| Cylinder Ø 31 mm DIN 53018 Z31 | 0.07 - 440 | 2,7 - 8.9*106 | ||

| High Shear Cylinder 25 µm gap HS25 | 6.9 - 4.6*104 | 1 - 5.8*105 | ||

| High Shear Cylinder 100 µm gap HS100 | 1.8 - 1.2*104 | 1 - 2.5*106 | ||

| Cone Ø 60 mm, 1° angle C60/1 | 0.9 - 6,000 | 1 - 9.8*105 | ||

| Cone Ø 35 mm, 1° angle C35/1 | 0.9 - 6,000 | 1.5 - 4.9*106 | ||

| Cone Ø 20 mm, 1° angle C20/1 | 0.9 - 6,000 | 8.0 - 2.7*107 | ||

| Plate Ø 60 mm PP60 | 0.47 - 3,100 | 1 - 2.5*106 | ||

| Plate Ø 35 mm PP35 | 0.27 - 1,800 | 6.5 - 2.2*107 | ||

| Plate Ø 20 mm PP20 | 0.16 - 1,000 | 61 - 2.0*108 | ||

| Starch Rotor Ø 40, 2 blades ST40 | --- | 10 - 100,000 | ||

| Vane rotor Ø 40 mm, 5 blades FL4 | --- | 5.6 - 1.9*107 | ||

| Vane rotor Ø 22 mm, 5 blades FL2 | --- | 54 - 1.8*108 | ||

Rheometer specifications

| Model | HAAKE RotoVisco® 1 | |

| Angular resolution | µ rad | 5 |

| Rotational speed CR-mode | min-1 | 0.0125 - 1,000 |

| Rotational speed CS-mode | min-1 | --- |

| Torque | mNm | 0.1 - 501) |

| Angle of rotation | ° | 360 |

| Bearing type | Mechanical bearing | |

| Type of motor | Micro stepper motor | |

| 1): The highest torque is not reached at the highest rotational speed. | ||

Temperature control options for HAAKE RotoVisco® 1

| Model | Temperature range | |

| Thermal fluid cylinder system TCL/Z | -20 - +200 °C | |

| Thermal fluid cone & plate system TCL/P | -20 - +300 °C | |

| Electrically heated cone & plate system TCE/P | -20 - +250 °C | |

| Electrically heated cone & plate system TCE/PC | -20 - +350 °C | |

| Peltier controlled cone & plate system TCP/P | -40 - +180 °C |

Software

HAAKE RheoWin® is a complete measuring and evaluation software package for all measuring modes. It controls the HAAKE RotoVisco® 1 instrumen and handles the measured data.

Some highlights are:

- Definition of measuring and evaluation sequences (Jobs) using Drag & Drop

- Fully automated measurement and evaluation in one job

- Broad selection of rheological evaluation methods

- Freely configurable ASCII data export

- Intermediate saving of measured data

- Real multitasking: simultaneous measurements with multiple rheometers

- Real 32-bit application for Windows® 98/Me and NT/2000/XP

- Password protected user-levels

- 12 operating languages available

- Tools for complying with the FDA 21 CFR part 11 requirements

- HAAKE RheoWizard: the expert system for creating new jobs

- Polymer tools (TTS = Time Temperature Superposition, relaxation time spectra, molecular weight distribution)

HAAKE RheoWin can be adapted to suit individual user requirements via special modules:

- Snap-Shot for quick characterization of an unknown sample

- Barcode control for workflow optimization (GLP)

- SAP interface for data exchange

- Automatic comparisons with reference data/master curves